Copper Loss and Line Insulation Monitoring on Subsea Umbilicals

March 9, 2018

Copper Loss resulting from Insulation Resistance monitoring devices and how to reduce such copper loss with V-LIFE.

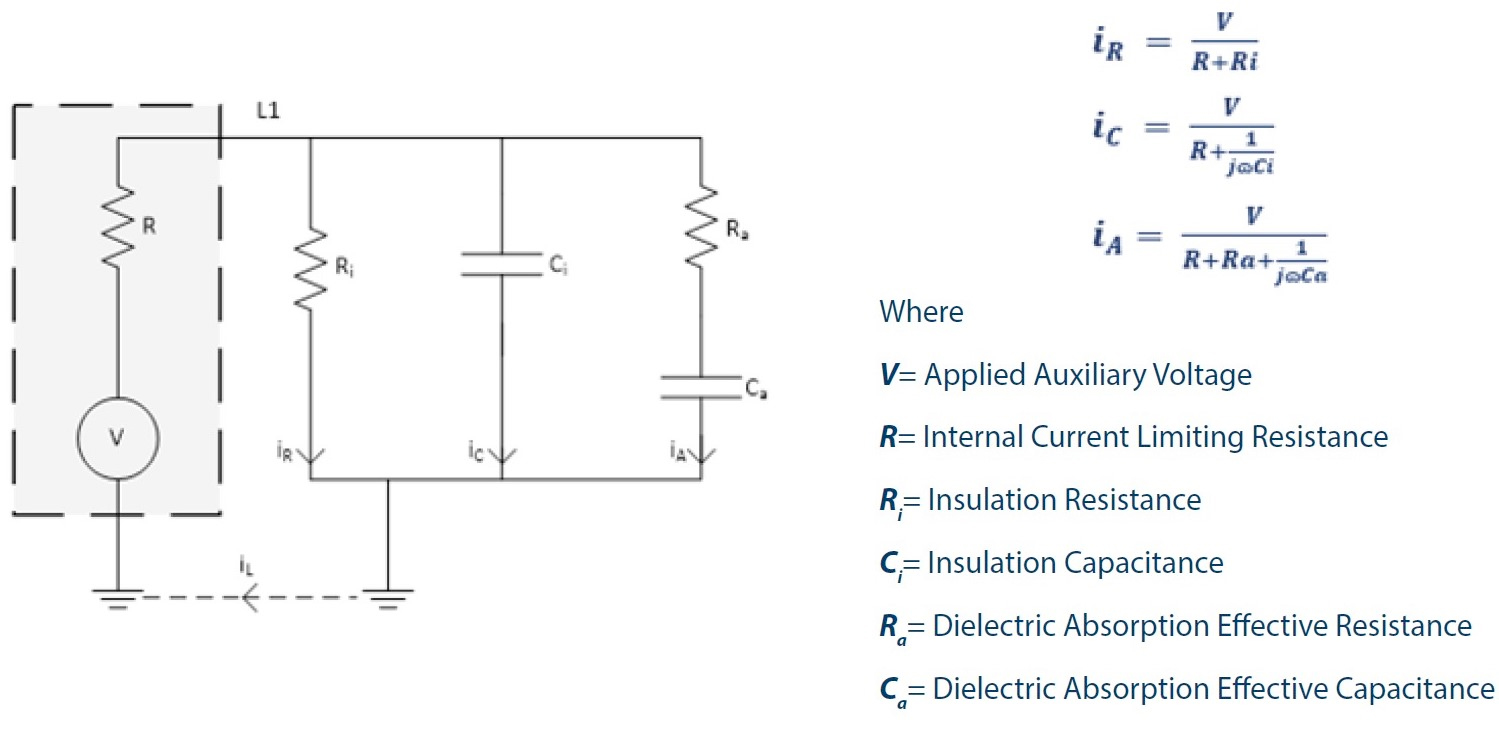

The principle of insulation monitoring is to apply a voltage between the copper conductors in a cable and earth and measure the current that flows. The figure below shows the equivalent circuit of the ‘earth’ to conductor connection.

The magnitude of the currents that flow are a function of the applied voltage, the frequency of the applied voltage and electrical characteristics of the insulation material.

If damage to, or degradation of, the insulation material results in seawater penetrating the insulation and getting into contact with the copper conductors then the leakage current flows through the seawater where there is dissociation of the dissolved electrolyte. This current flow results in copper ions moving into solution thereby causing copper loss at the wetted surface of the conductor.

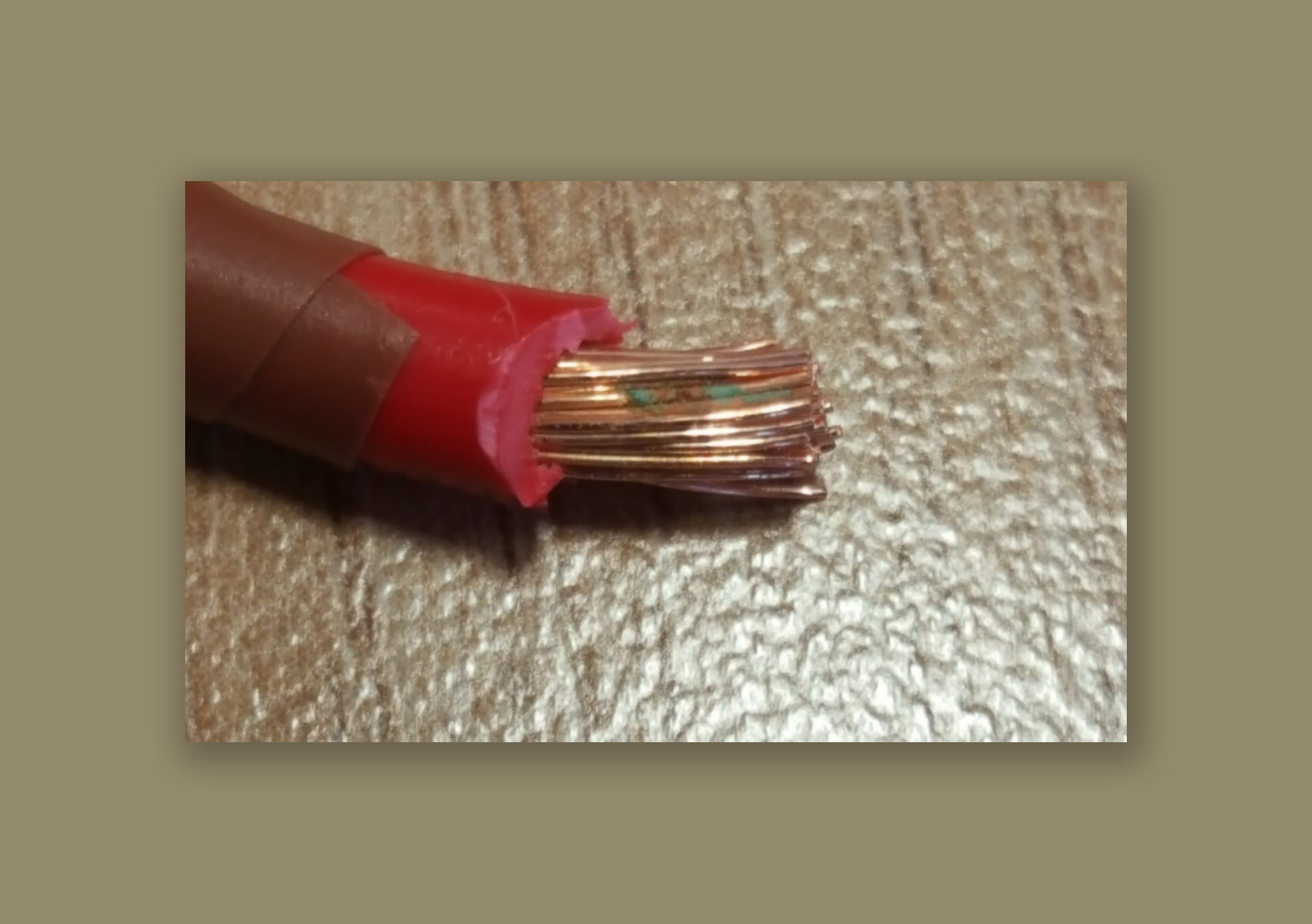

It can therefore be seen that the action of any Insulation Monitoring Device (IMD) [or Line Insulation Monitor (LIM)] will result in some damage to the copper conductors wherever they are in contact with sea water. As an example, the pictures below show the result of the action of a LIM unit that is commonly used in topside equipment on a damaged wire immersed in seawater.. The photographs show the condition of the wire after one week of LIM monitoring.

Damaged Cable Immersed in Seawater (Competitor’s LIM connected)

Cut away section of the same damaged cable showing area of copper loss

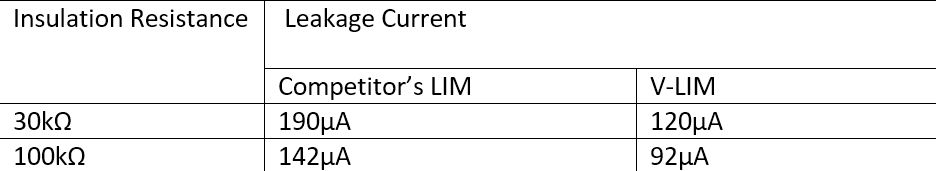

In any given degraded cable, the rate of loss of copper is directly proportional to the magnitude of the leakage current which is being sourced by the insulation monitoring device. This is clearly worse the lower the value of the insulation resistance. The table below compares the leakage current resulting from the Viper V-LIM with a non-Viper, but commonly installed LIM for a couple of low IR conditions:

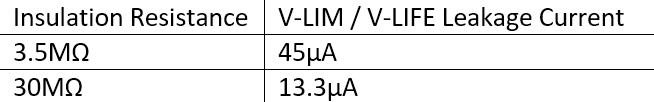

When the V-LIFE process starts (i.e. from initial connection), the leakage current and, therefore, the copper loss is no worse than that resulting from a standard LIM measurement. (i.e. V-LIFE results in less copper loss than a standard system with a competitor’s LIM connected). The application of V-LIFE blocks any pores in the insulation with a precipitate, thereby removing the seawater electrolyte and increasing the insulation resistance. As a result, the leakage current decreases and any copper loss is dramatically reduced. The table below shows the leakage current that will occur once V-LIFE has increased the IR:

It can be clearly seen from the above that the amount of copper lost from a conductor that is suffering from seawater ingress and is being monitored by a LIM device can be dramatically reduced by the application of V-LIFE.

If V-LIFE can be used to increase the insulation resistance to 3.5MΩ from an assumed starting point of 30kΩ, then the rate of copper loss will be a reduced factor of more than 4 times over the rate of loss due to the standard third party LIM. If the insulation resistance is increased to 30MΩ, then the factor increases to almost 15 times less copper loss.

Even with multiple V-LIFE restarts, the copper loss is never as high as that which would be experienced by connection of a standard third party LIM or IMD.