BLOG: The Ultimate Guide To Subsea Engineering

October 2, 2020

Subsea engineering is the industrial equivalent of fluid engineering and computer systems plus video games and the internet mixed in with a bit of the Wizard of Oz. It remains relatively new – certainly less than 50 years old – and is often seen as something ‘new-fangled’, even though it has been used extensively around the world for at least 35 years. Unlike the internet, though, it has not been widely heard of by the general public to whom the production of oil and gas for its daily energy requirements remain a relative mystery, like the man behind the black curtain in the 1930’s film.

What is Subsea Engineering?

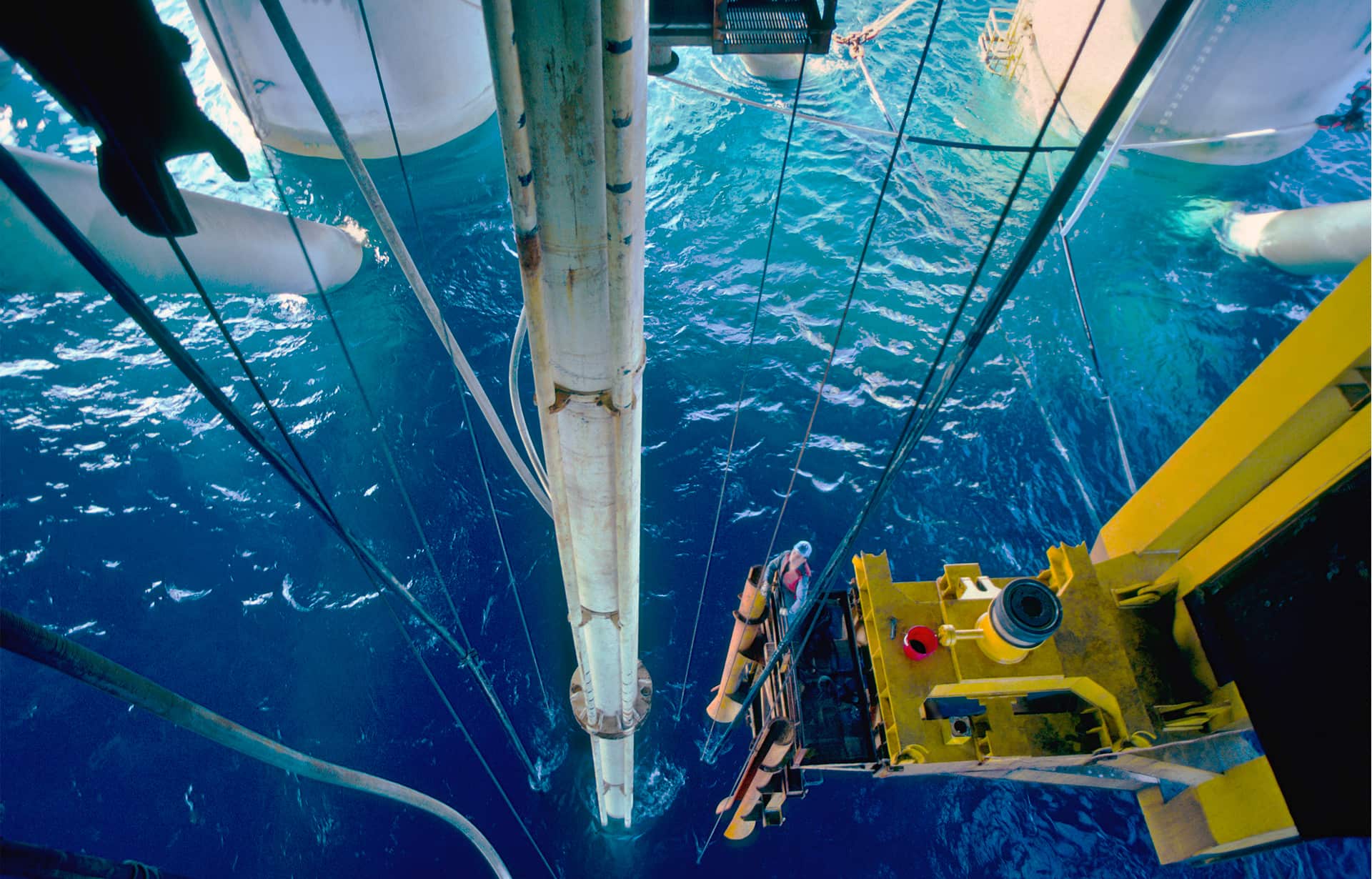

Subsea engineering is actually a high-tech subdivision of the oil and gas production industry. In the beginning, the oilfield was onshore in Pennsylvania, although the history of using petroleum products goes back thousands of years in the Middle East and southeast Europe. Just after World War II, the oil industry dipped its toes in the water for the first time, venturing offshore, albeit close to shore in very shallow water, in the Gulf of Mexico on wooden platforms, a bit like scaffolding.

After several more decades of refining offshore platform production technology – with platforms now made of steel – the next step was to install equipment on the sea bottom to produce oil and gas without putting personnel in harm’s way. There were small steps in using such equipment in the Gulf of Mexico and in Brazilian waters, but a more concerted drive to use such technology came in the North Sea in the 1980’s and 1990’s, first in British waters, followed by a rush of activity in the Norwegian sector.

How is Subsea Oil & Gas Produced?

In basic terms, subsea technology can be neatly put into three boxes. The first is how to get the oil and gas out of the ground safely without harming the environment. The second is how to transfer what is coming out of the wells to somewhere else for processing, or cleaning up. And third, how to make this equipment do what you want and do it safely.

The first piece of this puzzle is the subsea Christmas, or xmas, tree. People around the oil industry have been asking the question, who called a xmas tree a xmas tree first and when, for many years and no one seems to know the answer. What it is, in simple terms, is a complex tap, something like the taps that open and close in a sink or bathtub, allowing the oil and/or gas to come out of the ground in a controlled safe manner. On xmas trees, these taps are called valves.

Part two is the pipeline for transporting what comes out of the wells to another location. Pipelines are everywhere – for moving water and gas to homes and processed petroleum products, like aviation fuels, from refineries to airports. Those used in the oil and gas industry are often made from exotic alloys – combinations of different metals – to prevent corrosion.

The final piece of the jigsaw– and this is where Viper Innovations comes in – is the control system which is used to open and close the valves on xmas trees and sometimes to open and close similar types of valves associated with pipelines to stop or start the flow of fluids. They are also used to gather information, such as pressure and temperature, that originates from specially designed and located sensors, strategically placed around the subsea equipment.

Control systems have become increasingly complex and sophisticated over the years as equipment went into more challenging environments. Originally the control system worked a bit like the brakes on a car. The driver steps on the brake pedal which forces brake fluid down a narrow tube which moves the brakes to close. That was how controls, dubbed hydraulic systems, worked in the early days of subsea when the xmas trees were located no more than a few miles from its host platform.

Now wells are in much deeper waters – more than 2km below the surface in some cases – and the wells can be as far away as 100 miles (or 160km). Control systems now have to work much quicker than pushing hydraulic fluid. The signals to open and close valves are now electronic and reach the equipment in seconds, but the valves still have to be moved by fluids which are stored near to the valves. Such systems are now called electro-hydraulic because they combine electric signals and hydraulic force.

Subsea Engineering Expertise from Viper Innovations

Here at Viper Innovations, we have extensive engineering expertise in the specialist domains of subsea controls and umbilicals, but as a business we specifically focus on products and services for the integrity management and integrity monitoring of the subsea electrical distribution equipment such as electrical cables, connectors, junction boxes and umbilicals. Our award-winning products and services provide practical solutions for the real problems faced by our clients on a day to day basis whilst helping to take out cost and increase production efficiency.

Take a look at our market-leading products here or contact a member of our team to find out more.

Further Reading: V-LIFE – An Environmentally Friendly Alternative to Replacing Failing Subsea Electrical Equipment

Products & Services.

Viper Innovations provides control system distribution solutions for subsea oil and gas, railway and industrial sectors.