BLOG: Using Electrification and Technology to Support Rail Decarbonisation Vision

April 28, 2021

Working together to Target Zero: How Can Rail Innovators Contribute to Carbon Reduction?

Considering the recent events across the world, it is becoming plainly obvious that climate change is upon us and it is affecting everyone’s daily lives. Global warming and poor air quality are having a devastating effect across the globe, in our cities, coasts and countryside. Governments across the world have recognised the issue, and have committed and legislated to reduce carbon dioxide emissions to net-zero by 2050. Civil Institutions, Industries, National Infrastructure, Construction, Utilities and individual people in all walks of life are being challenged to make changes to do their bit to contribute to reducing global warming and creating cleaner air for us all to breathe.

The UK Government’s Energy White Paper and 10 Point Plan for a Green Industrial Revolution set out a direction of travel for the country. The rail industry itself has been challenged, even though it is already a very-low-carbon means of travel. The Transport Secretary, in 2018, challenged the industry to put a plan in place to decarbonise the railway and eliminate diesel-only trains from the network by 2040. The industry response to this has been to set up the cross-industry Rail Decarbonisation Taskforce, who published reports with the help of the RSSB in 2019, to offer insight and opportunity to both the technical challenges and the suite of strategic options likely to have the greatest impact. This, combined with research from RSSB, the Electrification Cost Challenge from RIA and other initiatives from RDG, UKRRIN and Rail Supply Group offer research, a strong set of recommendations, direction of travel and active support on reducing carbon.

Much of the focus, quite rightly, is on traction power – being by far the largest source of energy consumption on the network. Expansion of electrification, creative ideas on how to use a mix of technologies and processes to cover areas where it can never be cost effective to expand the overhead line and a strong move on battery and hydrogen powered units will all have a significant impact on carbon. The challenge of finding alternatives to diesel traction for freight is a significant endeavour and yellow plant will require innovative thought to rise to the challenge of eliminating carbon from railway operations.

But what about carbon in the wider rail industry? What can innovators like Viper Innovations do to pitch-in?

Rail Decarbonisation Strategies

Modal-shift is an obvious place to start and is a key theme across the range of initiatives being discussed. Vehicle journeys are still a huge contributor to carbon and poor air quality and according to Government research, the effect of the shift to low carbon fuels has been offset by greater numbers of journeys being taken, so moving as many of these journeys onto rail would make a significant positive impact on carbon and air quality.

So, what will help people make the decision to change and what aspects of this can supply chain innovators hope to effect? Well, working to create a right-time, 24/7 railway that extends unparalleled performance right out across the regional infrastructure would be a start. Mobility-as-a-Service initiatives in the wider supply chain can solve some of the issues associated with building connections to the rail network, but we can then take over and provide a consistent, dependable service that allows the user to feel in control of the journey from the local branch line to the final destination and back again.

This would mean applying the same importance to branch lines as we do to the mainline. Network Rail would need to apply a different set of business case metrics that take into consideration an assessment of how many journeys could be reduced, and by proxy how much carbon could be saved, by improving performance across the regional network. Modifying the business case to afford carbon a much higher weighting would need Regulator support and be backed in the CP7 settlement but this would enable the Regions and Routes to justify the application of technology where delay minutes alone cannot justify investment – and would fit into the strategic recommendations of the Rail Industry Decarbonisation Task Force, covering making business decisions based on customer, cost and carbon.

In addition to modifying the investment business case to make carbon reduction on a par with safety improvements or delay minute reductions, we can also consider the whole lifecycle of asset and incident management. Within the normal rail business cycle, we could introduce the concept of hidden carbon, in the same way that business improvement teams might refer to the hidden factory to classify elements of a process that are using resources but not adding value.

Environmental waste equates to business waste and generating carbon dioxide and other air-quality pollutants means expending energy for zero gain – and more properly stated, significant loss. Adding a highly-weighted carbon measurement to asset improvement or maintenance reduction initiatives would again ensure that new technology and process innovations were encouraged to focus on hidden carbon in the lifecycle as a key element of the design criteria, in much the same way that infrastructure projects now account for carbon savings in design. This would provide the dual benefit of ensuring that any given performance improvement project would analyse carbon improvements from a lifecycle analysis and report on them, providing leaders with an accurate picture of the whole carbon improvement picture.

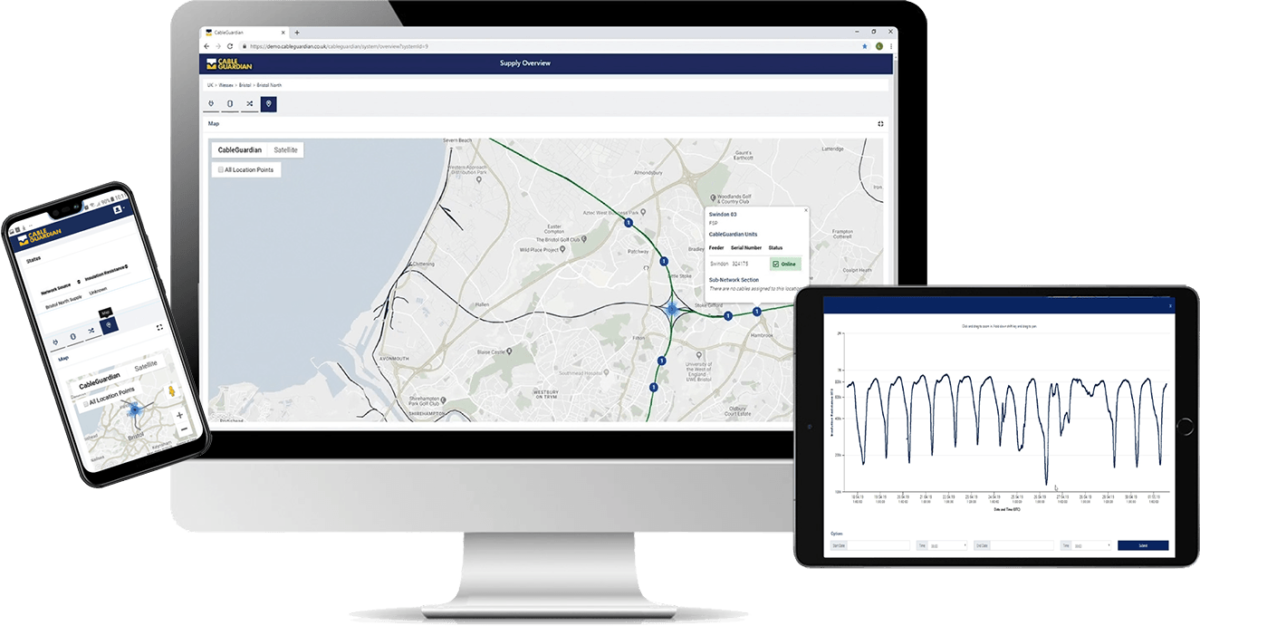

As an example of the issues considered above, for one of our innovations – CableGuardian – we have, as part of the development, considered the process improvements that can be gained from its use over the long term and the carbon that can be removed as part of its normal business cycle. Looking at the maintenance savings from replacing a very laborious and time-consuming activity – periodic inspection of lineside signalling cables – we can see there are thousands of vehicle journeys each year involved in performing the activity across the network. Travelling to and from site, vehicles left running on site, site movements of vehicles, each one of these journeys can rack up significant amounts of carbon, potentially hundreds of kilograms per vehicle, and considering that several vehicles would be involved in the activity, each cable section tested could be racking up thousands of kilograms of carbon. So the hidden carbon saving for what is primarily a huge safety and financial improvement is excellent over the lifecycle of the activity.

Looking at the performance improvement from CableGuardian, where it provides continuous monitoring of cable insulation and thus allows maintenance teams to replace cables prior to failure, also the improved delay per incident by allowing staff to pinpoint a cable theft or rodent damage immediately, the safety and performance improvements are very significant. However, the hidden carbon savings are equally significant. In the same way that thousands of kilograms of carbon would be generated with the vehicle movements related to maintenance, the same applies here. Maintenance and operations first-responders tasked with getting trains moving; maintenance staff chasing the failure, moving backwards and forward between access points; parts and equipment movement from stocking points; replacement bus services; de-training passengers; moving train staff – the list goes on and so does the carbon and air pollutants generated from any given asset failure.

So we can see that an innovation developed that was primarily aimed at safety and performance improvement, by default, can save significant amounts of carbon from the daily routine of rail operations. Even with the planned migration to zero tailpipe-emission vehicles, the improvements over the short to medium term are significant. So with support from the Regulator some modifications to the business case measures and KPIs for the regions, the rail industry could be making a more significant contribution to the environment, it just needs to measure it to be able to manage it.

So, to answer the question of what we can all do to contribute to target zero, the answer is a huge amount. Recognition from Regulators and Network Rail that hidden carbon is worth chasing and collaboration with supply chain to allow access to data could demonstrate easily captured carbon improvements for very little effort. Changes to quantifying innovation business benefits, specific carbon reduction KPIs for central and regional business and a wider consideration of how performance improvement right to the branch line will ensure that key innovations are rolled out beyond the main line. This will assist with modal shift, account for the hidden carbon within the process of asset failure remediation and degraded mode working, whilst providing the safety and performance benefits as part of the overall package.

So, with a little lateral thought and a more expansive set of carbon targets, we will see the rail industry taking what is already the best performing mode of transport for the environment to new levels of performance and leadership.

More About Viper Innovations.

Viper Innovations is a technological innovator serving the rail, subsea oil & gas and other industrial sectors with proprietary, award winning technology and products. Viper fosters a highly innovative culture, achieved through their people’s combined years of extensive experience and continued investment in research & development (R&D); this model has resulted in a strong pipeline of products and services.

Viper has taken proven technology developed for the harsh offshore environment and transferred this into products designed to improve the electrical integrity management of railway signalling power distribution networks. CableGuardian for the Railways has been designed to reduce maintenance costs and eliminate service affecting failures; caused by theft, vandalism or general degradation of signalling power cables.

See more: Digital Railway Maintenance – The New Rail Paradigm