CASE STUDY: Optimising Subsea Power Distribution Systems

February 4, 2020

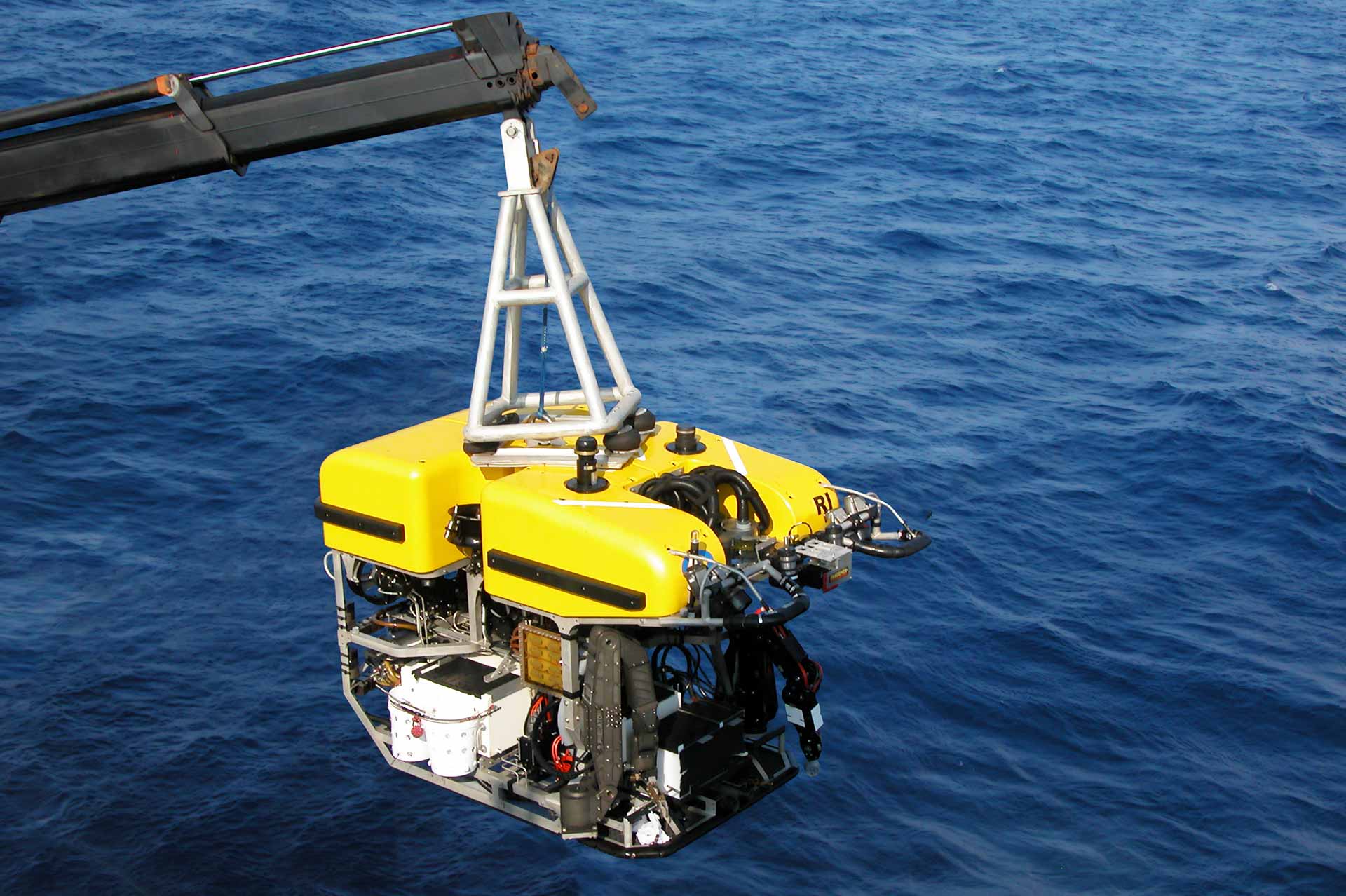

Viper Innovations has undertaken a number of electrical analysis projects acting on behalf of both Operators and Control System OEMs. In 2012, the engineering team were presented with a challenging analysis by one of the Super Major Operators.

The scope of work had Viper analysing different electrical systems, not only from a technical performance objective but from CAPEX, INSTALEX and OPEX commercial perspectives. Many months of work resulted in a key analysis document with intriguing results and which resulted in a paper that was presented at an Industry Conference being recognised with an award.

Problem.

Optimising power distribution for subsea systems is highly complex primarily as a result of the number of variables that are a given or can be selected. As an example the variables can include:

- Umbilical length (offset distance)

- Power consumption at consumer(s)

- DC or AC power distribution

- If AC, the transmission frequency (16 2/3Hz, 50Hz, 400Hz….)

- If AC, 1Phase vs 3 Phase

- Cross Sectional Area of the Copper

- Cost of power (and therefore importance of transmission efficiency)

- Region (and therefore cost and capability of installation vessels)

The client wanted to be able to quickly select what power distribution system should be specified for a given field development, and also for a given power distribution system what maximum offset or maximum power load could be supported. The client defined some battery limits for the analysis – eg minimum and maximum expected offset distances and minimum and maximum load case scenarios.

Solution.

Viper Innovations undertook thousands of analysis runs looking at different combinations of technology, voltages, CSAs, offsets and loads and created a number of multiple variable graphs which gave pictorial representation of limitations and suitable technologies. One example of the sort of graph generated is given above.

In addition to the technical analysis for each given cable design, a cost of manufacture was calculated as was a cost for installation (a function of the required vessel, lay speeds, and day rates). The electrical power transfer efficiency was also used to calculate the through life costs of supplying power. The result was a commercial model that would supplement the technical model to allow the operator to optimally select the technology that met both the project technical and commercial needs. The resulting report is now recognised as industry leading and has spawned a number of papers and presentations at conferences.

Get in touch with Viper Innovations.

Contact us to find out more about how our products & services could help maximise the operational life of your controls and electrical distribution equipment.

Our expert teams are equipped with the relevant experience and skills to provide support and to answer your technical queries, email us at enquiries@viperinnovations.com or via our contact form.