Insulation Resistance and the Risks of Unmonitored Cables

August 11, 2023

Once an exploration drilling campaign successfully finds new oil or gas reserves, engineers look to bring the asset to full production in a safe, swift and cost-effective manner. The optimal solution may use subsea equipment where manifolds, valves and risers fixed to the seabed are electrically powered and controlled from a platform or vessel topside.

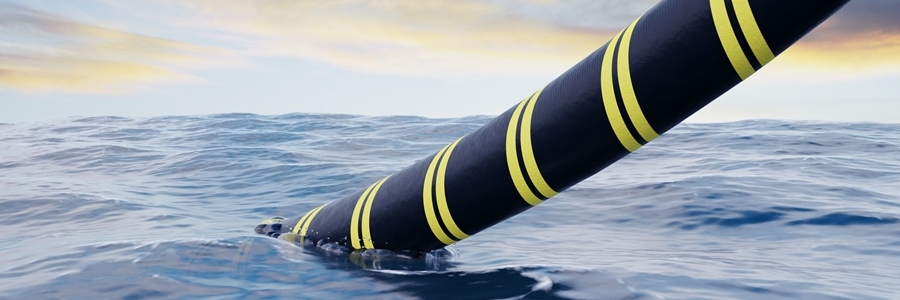

While this approach has a track record of reducing capital expenditure and unlocking value in marginal developments, operating subsea equipment brings its own challenges. Underwater electrical cables are critical to the operation of the subsea equipment, and loss of cable integrity can ultimately lead to field shutdown and loss of production revenue. The ability of a cable to protect its conductor is called its insulation resistance (IR). Monitoring, predicting and preserving the IR of a cable over the life of a subsea field is a science in itself.

What is IR and what does it do?

A subsea cable can have multiple copper conductors that carry electrical current in the form of power or communication signals, and an insulating layer which isolates the conductors from other conductors and electrical earth.

When the cable is new and the IR is high, power cables deliver the voltage and current needed by the equipment on the seabed without tripping overcurrent circuit breakers, or letting the voltage drop to a point where the Subsea Control Module (SCM) can no longer function properly.

Damaged and faulty cables will eventually allow seawater to ingress onto the conductors, causing low IR and leakage currents which can be hazardous to personnel and will eventually lead to system shutdown. The salt water also acts as an electrolyte, promoting a chemical reaction that can erode and weaken the copper conductors, which may accelerate the time taken for a fault condition to occur.

Although no insulator is ever completely perfect, cable IR – the ability to resist flow of leakage currents from the conductor into surrounding sea water, cable armour or other conductors – is vital to safe and compliant subsea operations.

Scratching the surface of IR failures

The reasons for loss of cable IR can be classified as either intrinsic or extrinsic factors. Extrinsic factors are those not native to the cable itself and can include stresses from incorrect handling during installation, seabed scouring causing abrasion damage to the surface of the insulator, or incorrect loading or ballasting placing strain on the cable. Impact damage from trawlers or remotely operated vehicles (ROVs) is also an extrinsic factor.

Intrinsic factors are associated with the construction of the subsea cable. Manufacturing issues or material defects can cause a low IR fault to develop even after years in service. Incorrect soldering or crimping of pins can damage connectors, and small defects in the polyethylene or polypropylene insulation material can escape quality checks during cable extrusion, leading to eventual IR breakdown once in the field.

Subsea electrical power systems are generally designed using an isolé terre (IT, unearthed) earthing philosophy to maximise availability. There is no Residual Current Device (RCD) protection in such a system, and it is vital that an Insulation Monitoring Device (IMD), also known as a Line Insulation Monitor (LIM), is installed to monitor for breakdown in insulation by measuring any conductor to earth leakage currents. However, even the monitoring voltages applied by a LIM can accelerate copper loss in a damaged cable by promoting the electrochemical reaction with sea water. Left unchecked, the cable is weakened to the point where it acts as a fuse, leading to an open-circuit fault that cannot be recovered.

IR monitoring and life extension strategies

It can be the case that deteriorating IR takes place gradually, as opposed to collapsing suddenly. Having permanent IR monitoring hardware properly configured with appropriate alarm setpoints is vital and is a legislation requirement. This information can allow the most effective life extension measures to be put in place at the earliest possible stage.

Installing the V-LIM Line Insulation Monitor from Viper Innovations gives operators some options that its competitors cannot. Not only can the V-LIM be configured to annunciate over a variety of industrial communications protocols for early warning, but it can actively help the situation in two unique ways.

Firstly, the V-LIM uses a lower voltage measurement signal which has been optimised to ensure that accuracy and repeatability are not compromised. This lower voltage has the effect of slowing the rate of copper loss from a cable with sea water ingress while maintaining the quality of its measurements, even at low IR levels. This can usefully extend the service life of a subsea cable with a low IR fault, when compared to competitors, without compromising the quality of the gathered data while still meeting the legislative IR monitoring requirements. In addition, all V-LIM units can greatly reduce further deterioration of the cable condition. By also enabling the V-LIFE IR recovery service from Viper Innovations, V-LIM units can play a role in actively healing cable damage and helping to prevent copper loss.

The common causes of IR failure are well known. Without monitoring and prompt action, its effects can be catastrophic to the operation of a subsea field. IEC 60364 requires that an IT earthed system is equipped with a monitoring or protection device, and a LIM is the best option for keeping the system in service in a hostile subsea environment.

Fitting a LIM is mandatory, so fit V-LIM and V-LIFE and take advantage of what these can do to remedy subsea cable faults and mitigate against expensive outages. Contact us using our contact form or email enquiries@viperinnovations.com for more information on IR monitoring and how to prolong the service life of your subsea cables and equipment.

Want to know more? Read all about Insulation Resistance testing and common causes of electrical failure in subsea cables in our recent articles here: