Technology Developed for Subsea Can Improve Railway Signalling Availability

July 31, 2017

These are exciting and challenging times for the UK rail industry; exciting because the future of rail is positive, yet challenging as Network Rail embarks on the necessary programme of expansion and upgrading to accommodate the inevitable growth whilst continuing to invest in maintaining an ageing infrastructure.

The Office of Rail and Road (ORR) – the independent safety and economic regulator for Britain’s railways – has highlighted the importance of maintenance in countering the effects of wear and ageing, and of keeping the network’s assets safe and performing as intended.

As part of the drive for a robust and future-proofed upgraded network, the regulatory authority has tasked Network Rail to achieve a 17% improvement in maintenance efficiency by 2019. This includes both planned and reactive maintenance. The authority has also challenged Network Rail to find innovative solutions to improve performance, reliability, availability, maintenance and safety of signalling power supplies.

The costs to the industry when failures occur are significant for both rail operators and rail users, with signalling power failures alone accounting for thousands of hours in service delays every year. At the same time the factors that result in power cable failure are complex and include degradation through aging, accidental damage, vandalism and cable theft.

With regards to the critical power supply infrastructure for points, track circuits and signalling, there is now a focus on intelligent condition monitoring that will enable the move from a frequency based inspection regime to one that is driven by actual asset condition and performance.

This fundamental change in approach to asset management is essential in reducing down-time and is one that has been successfully adopted in other industries such as subsea oil and gas, where a system failure means the likely shut down of oil production equipment with a resulting loss of production revenue. The subsea industry also has to deal with a challenging and costly repair regime with equipment such as electrical cables being located on the seabed in up to 3000m of water depth.

Fortunately, the technology to enable a proactive approach to electrical asset management within the railways is now available with CableGuardian, an innovation which has been born from within the subsea oil and gas industry.

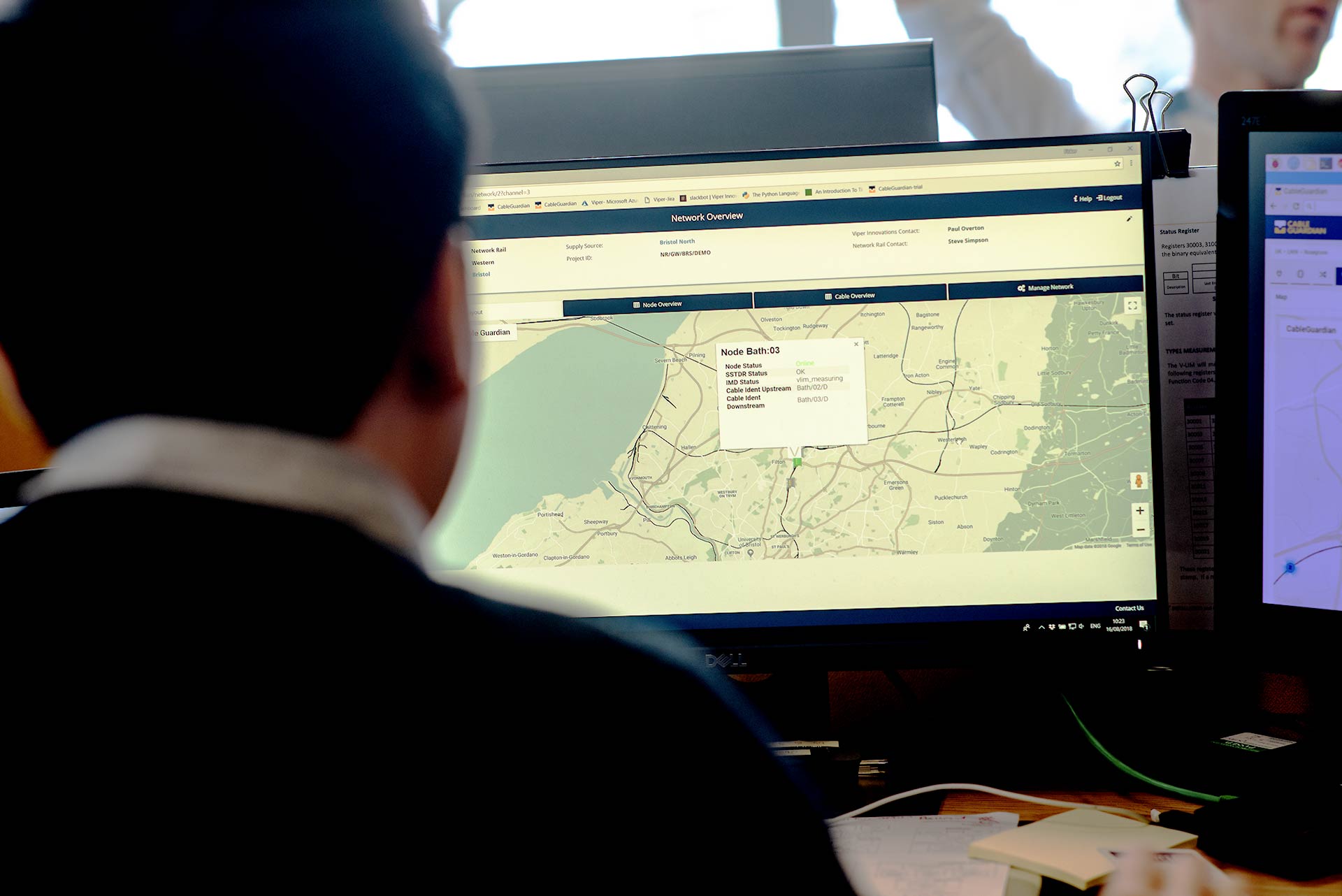

CableGuardian is the first platform to offer proactive monitoring, detection and location of both cable insulation and conductor faults on live signalling power distribution systems, offering a complete measurement and analytics package. The raw data received from a network of CableGuardian nodes is stored and analysed centrally.

CableGuardian is able to pinpoint the location of any electrical short, open, or transient failure with 98% accuracy. Installed in different locations throughout the signalling power distribution networks, CableGuardian returns data via 4G, trackside fibre, or standard wired Ethernet communications networks.

The end user receives not only health and status monitoring of cables, but fault location information in order to direct maintenance engineers for cable repairs or preventative maintenance. As well as the commercial and performance considerations, CableGuardian has positive implications for health and safety risks to both maintenance personal and the public by ensuring that failing cables are identified and alarmed well before they reach a state where there is a safety risk.

For issues such as cable theft, the system is able to instantly alarm on a first cable cut and direct British Transport Police, local police or security to the exact incident location as the theft is in progress.

The insulation monitoring technology, which is a fundamental part of CableGuardian, was developed as part of a Joint Industry Project model that saw a collaboration between Viper Innovations and a number of subsea oil and gas operators including BP, Shell, Chevron, and Total. The spirit of co-creative development between Viper Innovations and these major operators illustrates the degree to which the technology was desperately desired within the subsea oil and gas industry. The analytics software, which forms a fundamental part of the prognostic capability, was developed under a similar co-creative model that not only included major oil companies but also a UK university. The driver to identify where faults are and to predict where they are likely to occur has been a compelling one.

Most people understand the concept and the challenge of big data, yet few have the capability of implementing new digital solutions that can use big data. The CableGuardian analytics helps turn the mass of data returned from the monitoring nodes into useful and useable information about the condition of the system.

The ability to install such a prognostic and diagnostic system enables the asset manager to plan and prepare maintenance activity before problems cause system down time, or to quickly identify failures or incidences when they cannot be predicted.

The cable insulation monitoring technology embodied in CableGuardian has a unique capability to measure degradation and cable insulation parameters directionally. It is this capability that allows the CableGuardian nodes to monitor the entire power distribution network in a series of discrete cable segments.

To further enhance the capabilities of the CableGuardian technology, Viper Innovations invested in the US-based company LiveWire Innovation in 2016, acquiring a 35% equity stake in the recognised leader in Spread-Spectrum Time Domain Reflectometry (SSTDR).

LiveWire’s SSTDR technology was developed in part through $13 million of funding by the US Government and Department of Defense. SSTDR transmits small electrical signals along live communications or power cables and detects any anomalies along the length of the cable. Proprietary algorithms interpret the signals and convert the information into useable fault type and location information. The technology enables users to ‘see’ into their electrical infrastructure while in use and to pinpoint the location of faults.

Through the application of CableGuardian, a technology developed for use in harsh subsea conditions, the UK rail network of tomorrow will be hampered by far fewer incidences of delay through signalling power failures.