A Simple Guide to Spread Spectrum Time Domain Reflectometry (SSTDR)

November 16, 2023

Spread spectrum time domain reflectometry (SSTDR) is a live system monitoring and data collection technology. An evolution of the traditional time domain reflectometry (TDR) technique, applications of SSTDR include fault detection and location on live systems. In the rail industry, SSTDR technology is used for live cable monitoring and damage detection, enabling operators to track performance and identify faults before they cause system failure. SSTDR can be applied to applications in subsea oil and gas and other industries, delivering the same benefits to operators.

How does time domain reflectometry (TDR) work?

TDR uses reflectometry. It works analogous to radar, where a radio pulse is emitted and this reflects off an object, such as an aircraft. The reflection is received and interpreted to provide data, such as the aircraft’s distance, speed and direction. TDR uses transmission line theory and pulse reflection principles to detect changes in electrical cables. TDR transmits high-energy electrical pulses along the cable which reflect off changes of characteristic impedance. Analysing the magnitude and shape of the reflected pulse allows system features and potential faults to be determined.

However, the applications of TDR are limited because its accuracy is affected by other signals – or noise – on the line, requiring the system to be powered down to carry out the test. This means the approach cannot be used for system monitoring, diagnostics and fault detection in real time during operations. To provide actionable insights, most conventional TDR tests require an operative with the skill, experience and system knowledge to interpret the results.

How does SSTDR technology work?

SSTDR is evolved from TDR technology and, as its name suggests, SSTDR technology is a combination of traditional TDR and spread spectrum technologies. Originally rooted in secure defence communications technology, spread spectrum is the label used for several technologies where a signal’s strength is maintained, and its bandwidth expanded. This may appear counter-intuitive, as when the signal’s power is spread over a greater number of frequencies, there is no longer a distinct signal peak.

This is where pseudorandom noise signals come in, which are a key element of SSTDR. Pseudorandom noise signals are specific digital signals that are not interfered by and do not interfere with other signals on the line. The signals are so low that they sit within the noise floor of the system. Like TDR, the signals are generated, transmitted along the electrical distribution cables, and reflected by changes in impedance. The SSTDR system correlates the received reflection against the transmitted signal to generate a waveform. The differences between the transmitted signal and the reflection provide an indication of a fault on the line as well as a distance to the fault.

Algorithms are applied to analyse differences in the waveform patterns and automatically identify fault type and provide location information to the operator without the need for interpretation. A spread spectrum of frequencies can be used to complete the test. Higher frequency spreads provide accuracy at shorter distances and lower frequency spreads work best for longer cables.

Combining spread spectrum with TDR represents a significant breakthrough in monitoring and locating real-time changes in live electrical circuits, allowing electrical test and measurement. Here are some resources that provide more information on SSTDR.

What are the benefits of SSTDR?

SSTDR has two key benefits. It can:

- Detect changes in impedance that impact on performance, such as open and short circuits, arc faults, and hard-to-see intermittent events.

- Operate on live energised systems because the spread spectrum signals can be isolated from the host system noise and activity.

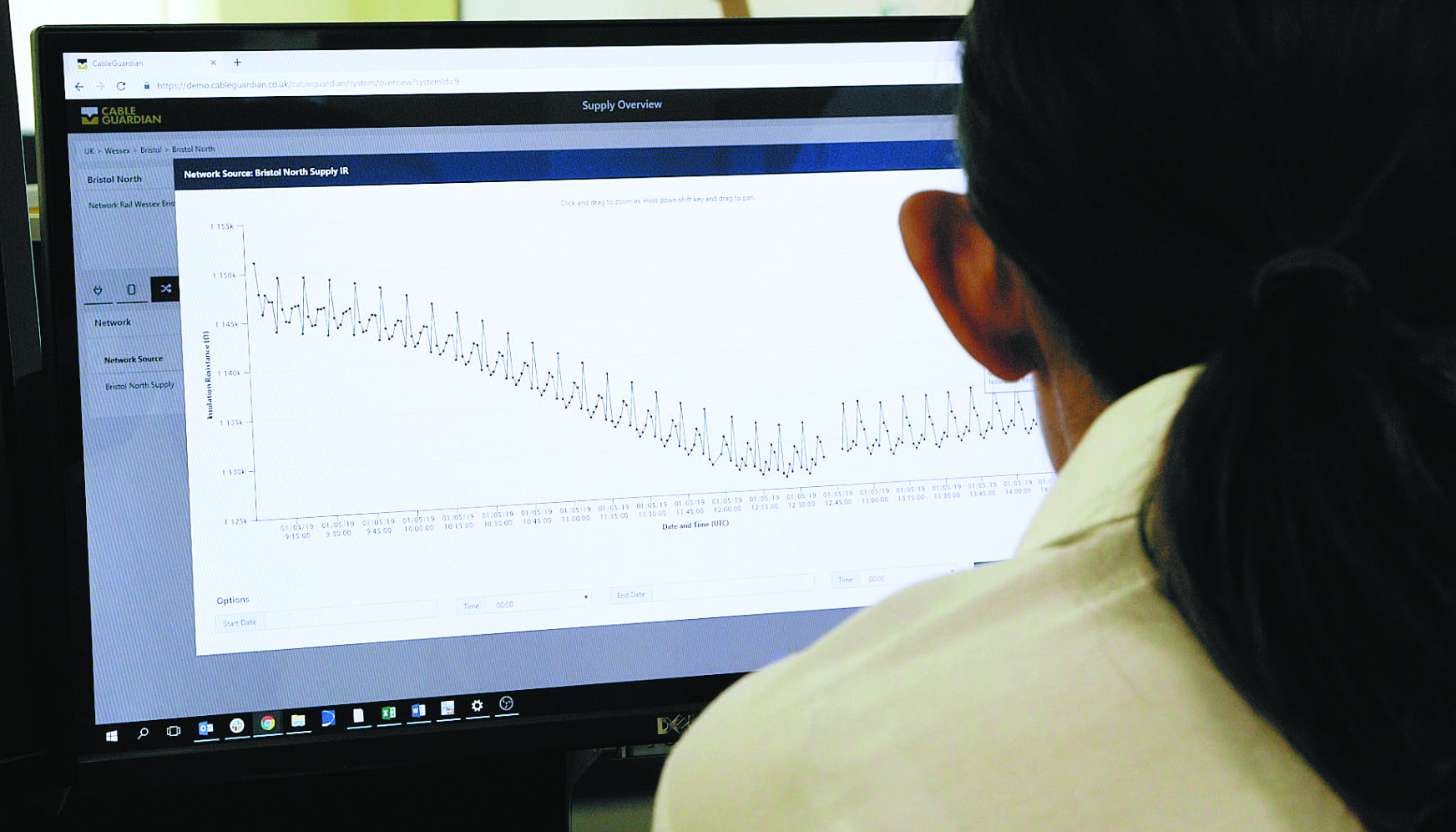

The game changer is the ability to operate on live systems and still detect and interpret the reflected signals from the surrounding noise. So small impedance changes caused by known conditions, such as connectors and loads, as well as inherent system noise, can be ignored. Unplanned events, such as hard or intermittent faults, are reported. Live monitoring means that events and their location can be logged as they happen and the ability to collect data to build a profile or ‘signature’ of a system is possible.

Applications of SSTDR

SSTDR sensor solutions are proprietary algorithms and correlation techniques in combination with electrical testing and measuring instruments that develop the ability to send and receive the spread of signals at a rate of up to 600 scans per second. These returns are then processed to determine what they mean and report the event to the system operator.

The most common application of SSTDR is the live detection and location of faults in electrical cables and wires. Any industry that uses critical electrical systems can apply an SSTDR sensor solution to monitor performance and detect faults in live cables, such as aeronautics, manufacturing, utilities, oil and gas, rail, nuclear and many others.

The TDR test will always have its place for carrying out spot tests on failed systems and for periodic testing. An SSTDR solution provides a powerful and proactive alternative with its ability to continuously monitor live systems. It enables operators to respond to emerging and critical faults as they happen, while eliminating the need for powering down the system to carry out intrusive tests.

Contact us using our contact form or email enquiries@viperinnovations.com for more information on how SSTDR solutions can identify faults in your subsea cables and equipment before they lead to system failure.

Products using SSTDR technology: