Applications of Spread Spectrum Time Domain Reflectometry (SSTDR)

October 16, 2020

Spread Spectrum Time Domain Reflectometry (SSTDR) technology can be utilised in a number of different variants and can work with most communications and control options in fully housed sensor modules for permanent installation. Sensor ‘engines’ are available in the form of fully engineered, credit-card sized printed circuit boards and multi-board stacks, as well as SSTDR chip-sets with corresponding reference designs for very high-volume applications. Two serial UART interfaces provide application communication to the SSTDR engine processor, which can provide further board-level solutions for other communication protocols like RS-282, RS485, USB or Ethernet interfaces. The module also contains a number of other interfaces to facilitate in the design and debugging, namely; JTAG, Reset, I2C that can be configured as GPIO, USB (providing power and drive mounting file transfer only).

SSTDR S100

The fully engineered SSTDR S100 ‘engine’ is a credit card-sized board and corresponding chipset. Engineers, OEMs, end-equipment manufacturers and system operators can quickly develop and integrate the S100 into their system to monitor live cables, wires and electrical systems for the detection and location of critical open and short circuits, arc faults, and hard to see intermittent events. Importantly, the S100 can operate on live systems. The S100 also allows system operators to collect valuable baseline data that can be used to help predict and prevent outages.

The S100 can be applied to industries such as utilities, aerospace, rail systems, PV array, telecoms, industrial and power systems. It enables live cable monitoring, live cable power theft/damage detection and cable harness testing.

Find out more about the SSTDR S100 here: https://www.viperinnovations.com/sstdr-s100/

SSTDR in Aeronautics

Interest in SSTDR started with military aeronautics to address problems with wiring and to address the costly dilemma of “no fault found” experienced when equipment in operation or flight experiences an electrical problem, yet no problem is detected back at home base. The same benefits seen by military customers are also relevant to commercial aircraft makers, Tier 1 suppliers and operators concerned with safety, security, reliability and the collection of data.

By embedding SSTDR into the core design of internal electrical systems, aircraft makers can provide users with the ability to monitor their system whilst in operation. The operational benefits of continuous monitoring with precise fault location includes increased revenue through less downtime, reduced maintenance costs and enhanced safety for employees and customers. For many operators, the ability to characterise their systems’ baseline performance and monitor for changes holds significant potential.

SSTDR in Rail

The rail industry faces many challenges with power cables which result in signalling failures and costly delays. These cables are substantial and can be an attractive target for thieves. Cables are also exposed to ageing environmental factors which can result in insulation degradation and cracking, the latter often leading to intermittent shorts (faults) when exposed to moisture. Detecting and locating these faults for the fastest possible fix can avoid service downtime during busy traffic periods.

The benefits are similar for the signalling infrastructure. The sustained and intermittent faults that develop can be seen and located. Significant insulation degradation that is sensed by monitoring equipment at a supply point, can be investigated by utilising SSTDR’s capability to ‘look into’ the cable infrastructure to locate critical impedance changes that have developed in the cable. As with detection of both hard and intermittent faults, removal or cutting of such cables can be detected and located immediately. Monitoring of signalling infrastructure using SSTDR is now available as part of Viper Innovation’s Network Rail approved CableGuardian system.

Application of SSTDR monitoring to trackside systems has shown that previously undetected and difficult to locate infrastructure faults can be found quickly and effectively. All cabling systems can suffer from various fault types; the severity and frequency depending on the installed environment, their use and the physical characteristics of the materials employed. Now SSTDR has started to prove its worth trackside, other applications, such as cabling reliability issues within the trains that run on the networks, can be investigated.

Find out more about the use of SSTDR in Rail here: https://www.viperinnovations.com/cableguardian/

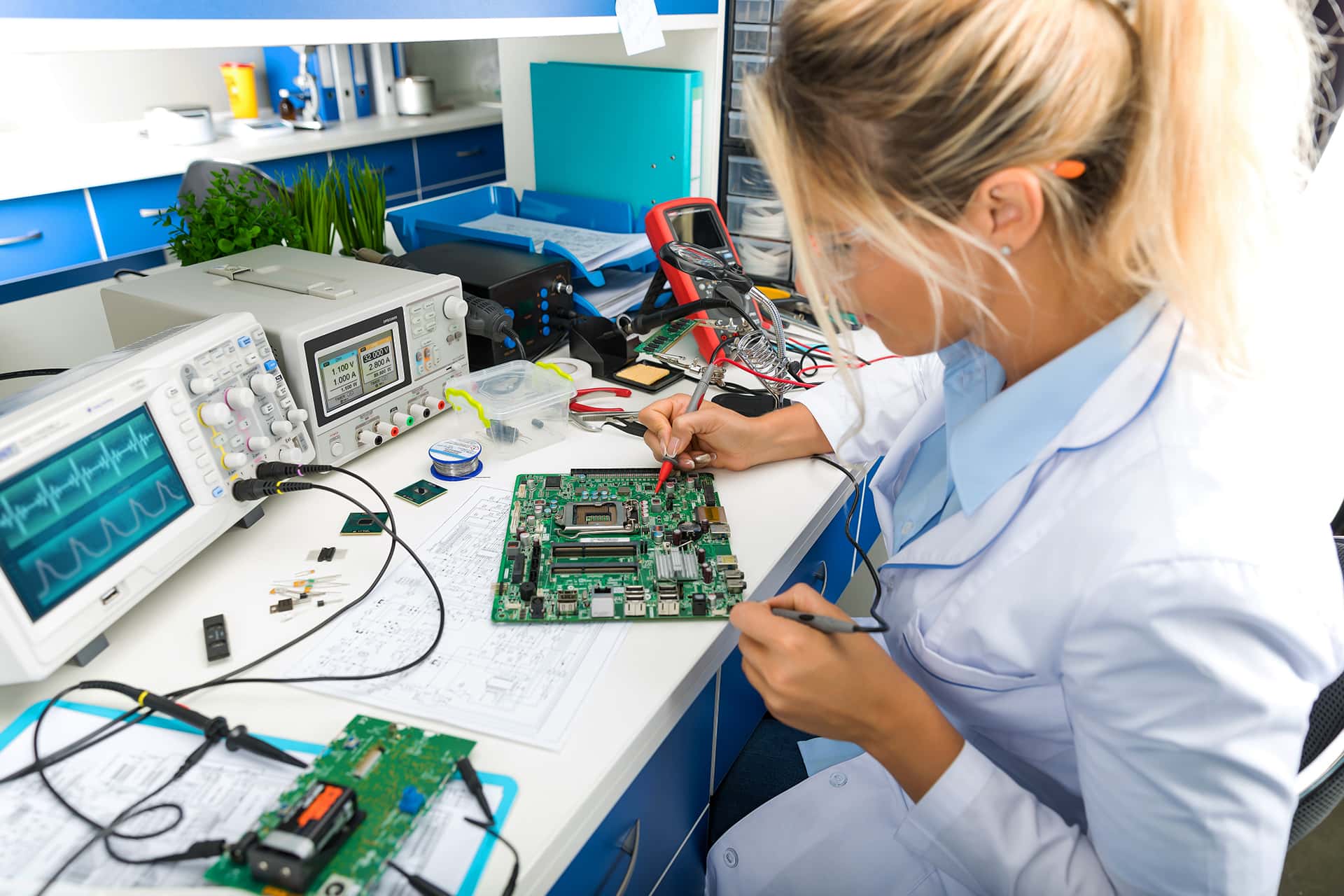

SSTDR in Manufacturing

Manufacturing environments are complex and highly automated, often operated on a twenty-four-hour, seven day a week schedule. Such facilities require the highest level of reliability possible to ensure constant operation, enabling any required maintenance and supporting activity to be carried out in a scheduled and non-disruptive manner. To ‘look into’ cabling infrastructure while manufacturing is in operation requires the monitoring system to be able to sense faults while power and/or communications are present, without interfering with the operation of the system being monitored. This can be achieved using SSTDR – enabling systems to operate without interference while being monitored for intermittent and hard faults; the type of faults that interrupt production on a regular basis.

Application of SSTDR monitoring to industrial production systems has shown that previously undetected and difficult to locate infrastructure faults can be found quickly and effectively. All cabling systems can suffer from various fault types; the severity and frequency depending on the installed environment, their use and the physical characteristics of the materials employed.

SSTDR in Utilities

Utility companies face numerous challenges in maintaining services and ensuring safety, while rolling out smarter network technology. The cabling infrastructure that physically connects the customer premises to the power distribution network varies in type, length and in the way it is connected to the network. Issues with cable damage, deterioration and tampering often remain undetected unless the cable damage leads to a power outage. Even then, detection is often down to the customer noticing power loss unless the meter is equipped to notify the utility company of the outage. In addition to damage or cable failure, cable tampering to enable power theft is an increasing issue worldwide.

To detect and locate these faults or tamper events requires the capability to see what is happening within the infrastructure while operational. To ‘look into’ cabling infrastructure while it is in operation, requires the monitoring system to be able to sense faults while power and communications are present, without interfering with the operation of the infrastructure being monitored. This has been achieved by using SSTDR. This capability also enables real time detection of unauthorised cable/wire taps for the purposes of power theft.

Whether the SSTDR capability is built into a device such as a smart meter, or is utilised within engineer site test equipment, power utilities can now monitor for faults in real time, speed up the location of both permanent and intermittent issues and prove power theft events without taking the customer out of service.

Related Reading

‘A Simple Guide to Spread Spectrum Time Domain Reflectometry (SSTDR)’ blog post: https://www.viperinnovations.com/a-simple-guide-to-sstdr/

SSTDR Flyer: https://www.viperinnovations.com/wp-content/uploads/5302-139097_R02_SSTDR_Flyer.pdf

SSTDR S100 Datasheet: https://www.viperinnovations.com/wp-content/uploads/5962-140989-R03_SSTDR_S100_DATASHEET.pdf

Products using SSTDR technology: