A Timeline of Subsea Innovation in the Oil & Gas Industry 1940-2000

(Part One)

July 19, 2021

This timeline of notable innovation in the subsea oil & gas industry celebrates changes between the 1940s and 2000; from the first subsea wells to Shell’s ambitious 1997 Mensa Project. This period was one of hugely significant milestones within the industry, with much of today’s basic equipment being developed and utilised for the first time.

First Subsea Wells

There are always disputes about historical events, and the first subsea well is one of them. The earliest reference is to a well in Lake Erie in the USA in 11m of water in the 1940s, which used a surface xmas tree. Moving forward nearly two decades, Shell completed a subsea well in the Gulf of Mexico in 1961, and Esso followed suit in 1964 (803U-3).

First Subsea Production System – 1973-74

Esso Subsea Production System (Garden Banks 70/71) Gulf of Mexico – The SPS was the first serious foray into a full-scale system and had several offspring. It was the father of the Underwater Manifold Centre (UMC) in the UK and the grandfather of the Snorre system in Norway. It included several concepts that either did not come into common use for decades or were never used again, such as a subsea processing module and a nuclear power source.

One-Atmosphere Chambers – 1979

Garoupa, Brazil – Petrobras has always done things differently to most operators, and it chose to use seabed chambers for this development in which the wellheads were installed in dry conditions. This technology, initially developed by Lockheed Petroleum Services (later known as CanOcean), was first deployed by Shell in the Gulf of Mexico in 1972 for a single well in 115m and later expanded in 1975 to incorporate manifolding for three wells in 75m in Eugene Island 330. The Petrobras system was even more extensive, eventually covering nine wells in water depths to 166m, although the chambers were rated for 365m or 1,200ft.

Underwater Manifold Centre, UK – 1982-83

What made this development unique at the time was it was the first application of a technology that was not actually required for the project. Operator Shell UK Expro, a 50/50 joint venture between Shell and Esso, decided to deploy the UMC, the offspring of Esso’s SPS (some common design features plus the re-use of manipulator tools) on the Central Cormorant field as a testbed for a number of technologies and future deepwater developments. Some of these included the use of both template and satellite wells; multiplexed electro-hydraulic controls; flexible pipe; et al. While the project was seen as a success – it is still operational 40 years later – it did take a very long time to come to fruition (more than five years). It was also responsible for setting a large number of engineers en route to a career in subsea engineering. An extraordinary number were involved in the project – or at least their CV’s say so!

First Purpose-Built Floating Production Systems – 1986

It was a coincidence that the deployment of the first two purpose-built Floating Production Systems (FPS), but of different types, occurred in the same year in British waters. Semi-submersibles had been used for floating production, but they were all converted drilling units. Sun Oil’s Balmoral semi FPS was the first designed and built specifically for production. Many were to follow. Also, in the same year, Norsk Hydro put the newly-built Production Test Ship (PTS) Petrojarl 1 to work as an early production system on the Oseberg field in Norway. As with semis, converted tankers had been used for floating production in the past, in the Far East by contractor Bluewater and by Shell at Castellon, offshore Spain, but this one was the first of its kind, to be followed in 1990 by BP’s Schiehallion. It is now the concept of choice for deepwater production around the world, particularly where transporting processed fluids by pipeline is impracticable and uneconomic.

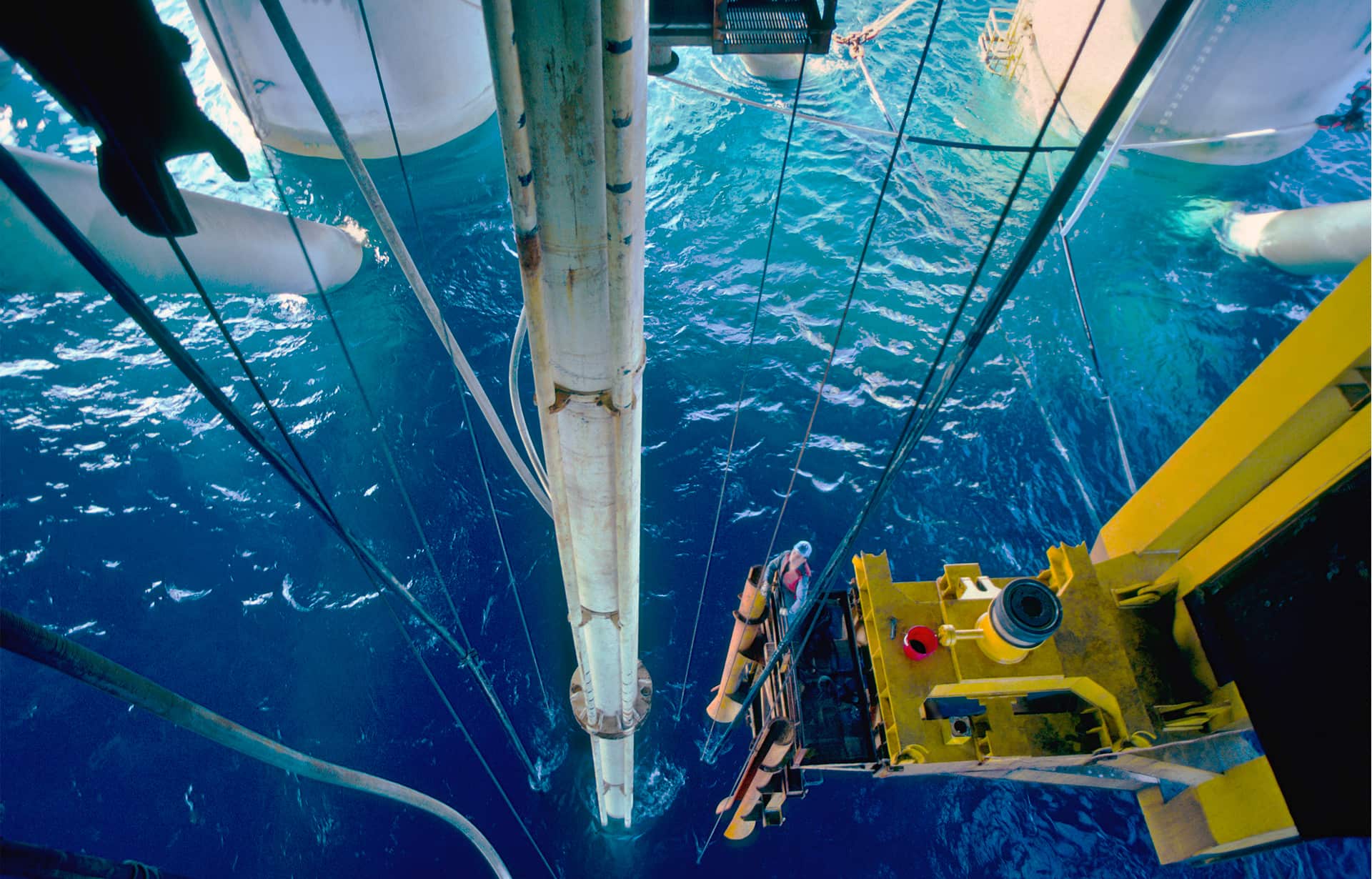

First Diverless Subsea System – 1986

Gullfaks Subsea – As most subsea production systems to date had been in diver-accessible waters, no reason was seen to design such systems for diverless operations. Statoil (now Equinor) saw its operations closing in on 200m and, with some foresight, decided to engineer its first subsea wells for operations and intervention using Remotely Operated Vehicles (ROVs). This was not a total success, with one part of the installation process forgotten which required a diver’s assistance.

Long Tieback – 1992

Togi – Much subsea R&D was focussed on Norway in the 1990s. This was an important development on controls for long distance tiebacks. Troll Oseberg Gas Injection (TOGI) was developed to deliver gas from the Troll field for injection on the Oseberg field to provide pressure support for the reservoir. The tieback distance was 48km, but the control system, developed by Vetco Gray, was tested roundtrip for 96km. For the long distance communications, Vetco Gray used a modem developed specifically for the project by the Hughes Aircraft Company. Other features were the deepest remote pull-in of a large diameter pipeline (20in) and the use of Remotely Operated Tools (ROTs) rather than ROVs. This was used to good effect when the sealing plate for the pipeline pull-in was fouled.

Going Deep – 1,000m 1991

Most of the deepwater records in the offshore sector have been set in Brazil, and the first subsea well in 1,000m was achieved here on the Marlim South field.

Multiphase Leaps – mid-1990’s

Multiphase technology became all the rage in the 1990s as produced fluids became more complex, and transportation distances became longer. While there was a good deal of research work into fluid behaviour – a major programme was carried out by IFP in France with the support of Total and Elf as well as Statoil – equipment developments were commercial enterprises. One of the leaders was Framo Engineering in Norway. It supplied the first multiphase pump to Norske Shell, developed under its SMUBS programme, for installation on the Draugen field. Later it provided the first multiphase meters, initially for the East Spar long distance gas tieback in Australian waters and then for West Brae in the North Sea.

Horizontal Wells – 1995

Troll West – Horizontal wells were not new and neither were subsea H-wells, but they had never been used to such an extent as here. When Norsk Hydro first proposed the development of the so-called thin oil zones (22-26m), it suggested producing 100 million barrels. Such has been the success and accuracy of these wells that 1 billion barrels have already been produced, with more to come.

Long and Deep – 1997

Mensa – While Shell loved its Gulf of Mexico (GoM) tension leg platforms in the 1990s, it still had subsea on its mind. After taking on Popeye, it looked for something even more demanding. At 1,615m water depth with a 109km tieback distance, Mensa was possibly the most challenging subsea project ever. It also had one of the most dramatic early failures when the radical split tree parted at its connector. The problem was corrected and the field remains in production nearly 25 years later.

Finished part 1? Now read part 2!

Click here to read part 2, which outlines notable subsea innovations from 2000 onwards.

Viper Innovations takes pride in providing cutting edge subsea distribution technology and expert level consultancy services to provide practical solutions for the real problems our clients experience on a day-to-day basis whilst helping to take out costs and increase production efficiency. Learn more about our award-winning product and service offering here: