This film addresses what has been regarded as the ‘traditional approach’, which is subsea intervention, to find and replace damaged hardware.

WHAT SHOULD I BE CONSIDERING.

One option that all operators will consider is replacement of the failed hardware. The first challenge is to identify what hardware has failed before any replacement can be assessed. Typically, fault location includes the use of a systematic fault location procedure with an ROV or divers. Such a procedure is likely to require the disconnection and reconnection of subsea hardware such as electrical distribution units or electrical flying leads. This in itself creates a further risk of failure to the subsea equipment. Disconnecting and reconnecting electrical connectors in a subsea environment, especially when the connectors are likely to have been in place and undisturbed for many years carries a high probability of further water ingress and failures to sensitive water blocking barriers within the connectors. Thus the fault diagnostics can, and regularly do, reduce further the integrity of the system and may degrade the system to a point where it becomes un-operational – all as a result of an intervention to fault-find.

Once the fault has been located, again, an intervention with ROV or diver will be necessary to replace the failed equipment. In the case of an umbilical replacement, clearly the intervention planning, costs and vessels are much more significant, but in all cases, the economics of intervening are a function of vessel costs (driven by market utilisation), availability of suitable vessels in the given region and lead times of replacement hardware or fault diagnostics hardware.

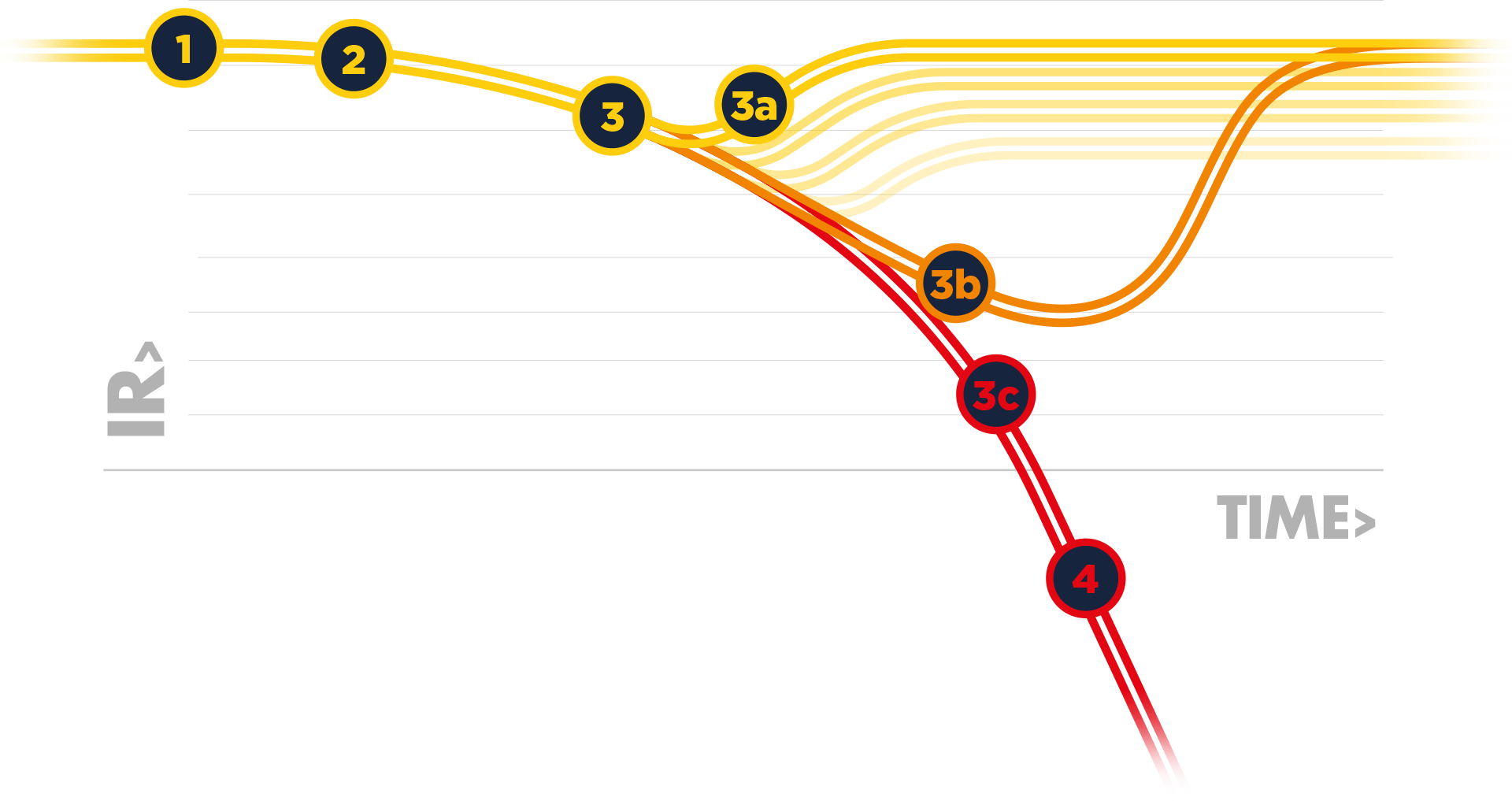

The decision to replace failed hardware is therefore affected by many factors – ranging from technical to economic, and the decision-making process is complex with no guarantee of a successful outcome.